Product Costs in Accounting: Definition & Examples

By analyzing a company’s cost structure and comparing it to its competitors, investors can assess whether the firm is setting appropriate prices for its products or services. A well-priced product or service not only secures customer loyalty but also generates superior returns for investors. If the product cost is too high, the bakery may need to find ways to reduce it, such as by buying ingredients in bulk, optimizing the baking process, or negotiating a better deal on kitchen rent. By understanding the cost of producing each product, businesses can make informed decisions about where to invest their resources to maximize profitability. One major issue in all of these contracts is adding too much overhead cost and fraudulent invoicing for unused materials or unperformed work by subcontractors. Management might be tempted to direct the accountant to avoid the appearance of going over the original estimate by manipulating job order costing.

Understanding Production Costs: Definition, Types, and Calculation for Institutional Investors

- For example, a company with exceptionally high production costs may experience lower profitability, potentially impacting its stock valuation.

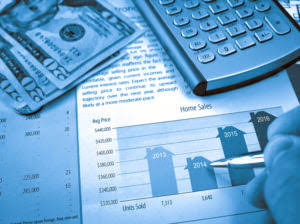

- Data like the cost of production per unit or the cost to produce one batch of product can help a business set an appropriate sales price for the finished item.

- The raw materials inventory department maintains a copy to document the change in inventory levels, and the accounting department maintains a copy to properly assign the costs to the particular job.

- Product cost, also known as cost of goods sold (COGS), is the total cost incurred to produce a product.

- In conclusion, understanding various processes and methods for calculating production costs, including absorption costing and variable costing, is essential for institutional investors.

Product cost, also known as cost of goods sold (COGS), is the total cost incurred to produce a product. It includes direct costs such as raw materials and labor, as well as indirect costs such as factory overhead. unearned revenue For example, a furniture factory classifies the cost of glue, stain, and nails as indirect materials. Nails are often used in furniture production; however, one chair may need 15 nails, whereas another may need 18 nails.

How Are Production Costs Calculated?

The final T-account shows the total cost for the raw materials placed into work in process on April 2 (vinyl and ink) and on April 14 (grommets and wood). The journal entries to reflect the flow of costs from raw materials to work in process to finished goods are provided in the section describing how to Prepare Journal Entries for a Job Order Cost System. Returning to the example of Dinosaur Vinyl’s order for Macs & Cheese’s stadium sign, Figure 4.7 shows the materials requisition form for Job MAC001. This form indicates the quantity and specific items to be put into the work in process. It also transfers the cost of those items to the work in process inventory and decreases the raw materials inventory by the same amount. The raw materials inventory department maintains a copy to document the change in inventory levels, and the accounting department maintains a copy to properly assign the costs to the particular job.

- It’s important to note that this is a simplified formula and actual product cost calculations can be much more complex.

- Since product costs include manufacturing overhead that is required by both GAAP and IFRS, product costs should appear on financial statements.

- Understanding the various types of production costs, how they are calculated, and their impact on pricing strategy is essential for institutional investors when evaluating potential investments.

- When the product is sold, these costs are transferred from inventory account to cost of goods sold account and appear as such on the income statement of the relevant period.

- Production cost analysis provides valuable data to evaluate target companies in terms of their potential synergies, economies of scale, and operational improvements following the merger or acquisition.

- Read advice from restaurant owner John Gutekanst about the importance of understanding food costs and his approach to account for these in his pizzeria.

How Do Production Costs Differ from Manufacturing Costs?

Fortunately, the accounting system keeps track of the manufacturing overhead, which is then applied to each individual job in the overhead allocation process. Product cost appears in the financial statements since it includes the manufacturing overhead that is required by both GAAP and IFRS. QuickBooks ProAdvisor However, managers may modify product cost to strip out the overhead component when making short-term production and sale-price decisions. Production costs refer to all the direct and indirect expenses a company incurs when manufacturing a product or providing a service that generates revenue for the business. These costs include labor, raw materials, consumable manufacturing supplies, and general overhead.

Product costs (also known as inventoriable costs) are those costs that are incurred to acquire, manufacture or construct a product. In manufacturing companies, theses costs usually consist of direct materials, direct labor, and manufacturing overhead cost. While both terms may seem interchangeable, they represent different aspects of a business’s operations. Direct costs are expenses that can be directly attributed to a specific business operation or process. For instance, drilling rigs, labor, and crude oil purchases are all considered direct costs within the oil industry. Indirect costs, on the other hand, are more general overhead expenses that support product costs consist of multiple operations or departments within an organization.

Data like the cost of production per unit or the cost to produce one batch of product can help a business set an appropriate sales price for the finished item. Product costs are initially attached to product inventory and do not appear on income statement as expense until the product for which they have been incurred is sold and generates revenue for the business. When the product is sold, these costs are transferred from inventory account to cost of goods sold account and appear as such on the income statement of the relevant period. For example, John & Muller company manufactures 500 units of product X in year 2022. Out of these 500 units manufactured, the company sells only 300 units during the year 2022 and 200 unsold units remain in ending inventory.

Ethical Job Order Costing

By closely examining a company’s cost structure, investors can discern its competitive advantages, assess potential risks, and forecast future growth prospects. Properly interpreting production costs allows investors to make informed decisions regarding their investment strategies and portfolio allocations. Direct laborers are the employees or the labor force that gets directly involved in producing or manufacturing finished goods from raw materials. The direct labor costs are the salaries, wages, and benefits (like insurance) paid to these labor forces against their services.